Top Benefits of 3D Modeling for Design Development and Manufacturing

Top Benefits of 3D Modeling for Design Development and Manufacturing are reduce design time ,quality and precision, easy design developmentetc. It helps engineering professionals come up with the most innovative solutions.Because of the technological aspects and challenges have been addressed the 3D design models are extremely accurate .3D printers and rapid injector molding make it easier to create early-stage prototypes, perfect for testing. This innovation can extend the value of a prototype, and often speeds up the production process. This new way can help prototypes reach levels of value in some situations, speeding up the product development process substantially

3D modeling is a way to start a project before you even begin Design, because it allows engineers to not only envision what they want the product to look like but also the precise details of how they will get there.

Utilizing the entire design and manufacturing process will help companies increase productivity, creativity and collaboration. With 3D modeling, companies can provide an overall DNA of the enterprise framework and optimize the entire process..

3D models are a great choice for manufacturing because they are easy to create and can be used as prototypes.

What is 3D Modeling?

To create a 3D image of an item, you add points (vertices) to form a mesh in the virtual space. These points are defined (mapped) by the designer.

Designing a product in 3D can mean anything: thoughts, ideas, items or assets. Product design firms are encouraged to start using this technology sooner rather than later, as there are many benefits to using it.

This allows for faster, more accurate prototyping. 3D Models for Product Prototyping provide outstanding value for manufacturing.

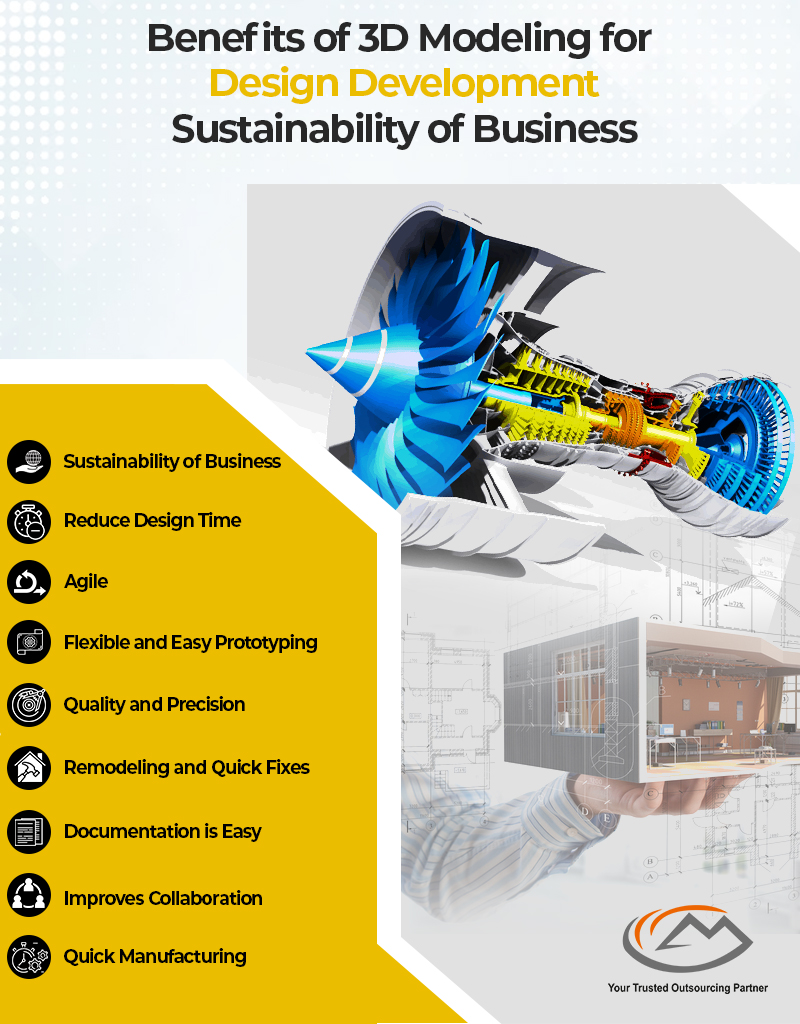

Benefits of 3D Modeling for Design Development

Sustainablity of Business

Employing 3D modeling, businesses can minimize their number of physical prototypes and save on waste.

Reduce Design Time

3D modeling can aid in reducing design time and costs. 3D CAD software enables you to review, test, and update each component of a structure or product before going into production. This will give you the ability to view an object from any angle, which shows flaws that may otherwise be difficult to find.

Agile

Digital renderings can be created quickly and transmitted in seconds. These models are not limited to the physical, but can be customized to reflect individual customers’ needs.

Flexible and Easy Prototyping

A 3D model can be used to create a prototype before a product is made. The designer can use sketches, hand drawings, and concepts to create extensive prototypes that can be modified without wasting resources on creating new sketches of the product and its many angles.

Quality and Precision

With the use of 3D scans and modelling, clients can generate precise virtual spaces for their company boards, even before design begins. With the assurance of quality

Design Development is Easy

Designers would make a lot of drafts and change their designs. New prototypes would be ordered for each design and the new design was only accepted when it was perfect.

Companies no longer need to order many prototypes for a one-of-a-kind design. A 3D artist can generate digital renderings of the company’s concept, eliminating the need for them to produce their own prototypes.

Remodeling and Quick Fixes

Making prototypes is an expensive and time-consuming process. With 3D modeling, you can identify any design flaws ahead of time without the need for a prototype. 3D objects that faithfully represent the blueprints can be tailored to work with CAD software, helping to catch errors and prevent production delays.

Documentation is Easy

Employers can use 3D models to document the complete manufacturing process. They serve as a shared reference point and facilitate better communication between stakeholders and designers. Employers are able to preserve iterations with ease, and can use them as reference points for finding errors or inaccuracies in the design.

Improves Collaboration

With 3D modeling, every team member involved in the project can access new data. It ensures all members are on the same page with models and sketches.

The unified, automated forum simplifies communication among the team, making teamwork much more effective. Using 3D modeling, designers, engineers and manufacturing staff can collaborate on the product development, helping to finish construction projects on time and on budget.

Quick Manufacturing

3D modeling is quicker than traditional methods, and can produce a market-ready product in less time.

Because the same 3D model is also used to design and create the plastic injection molded product, production time is reduces. Similar design qualities are transferred to CNC machines for metal products, which can produce prototype parts swiftly and with constant exacting geometry and tolerances.

Advantage for Marketing

3D models are useful for product promotion, display, or ads. Using these models has boosted marketing efforts among manufacturers by a thousand words.

Using a 3D model makes it more interesting for prospects, which in turn increases your chances of winning the business. This technology also speeds up project approval in the design industry.

3D models help engineering design the most innovative solutions. They reduce the chance of costly errors in development, by ensuring consistency across designs. 3D modeling is at the forefront of product design, with solutions that are accurate and abide by technological constraints.

As cloud-based Internet solutions, as well as new devices and platforms expand, the use of 3D CAD modeling has expanded to a considerably larger user base. As a result, 3D CAD modeling has become more practical and efficient in new fields like mechanical engineering.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global CAD, CAM & FEA News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, CAM & FEA services outsourcing partner serving the needs of the Mechanical, Millwork and Automotive industry since 2004. MILESTONE focuses on the unique needs of clients and believe in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with Product Design, 3d Modeling, Drafting & detailing, Reverse Engineering, FEA Analysis and more. We support multiple software including AutoCAD, Solidworks, Catia, NX, Inventor, Solidedge & Ansys etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

For more queries regarding any of the above-mentioned topics, feel free to connect with us on our website www.milestonetech.net or contact us on +1-844-598-0005