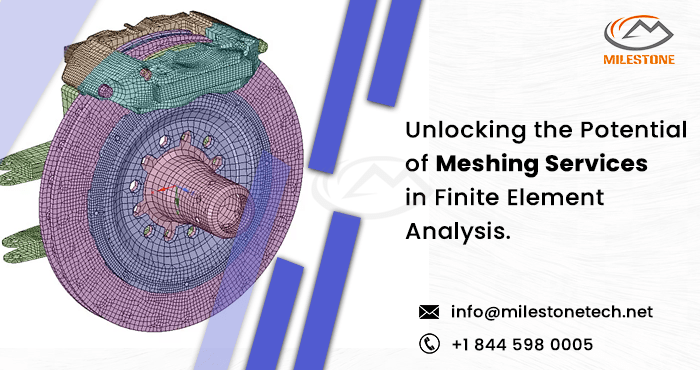

Unlocking the Potential of Meshing Services in Finite Element Analysis

Finite Element Analysis, or FEA, is a powerful tool used by engineers to simulate and analyze the behavior of complex structures and systems. Whether it’s designing a skyscraper, testing a new aircraft wing, or optimizing a mechanical component, FEA plays a crucial role in ensuring the safety, efficiency, and cost-effectiveness of engineering projects. One of the fundamental aspects of FEA is meshing, a process that divides a complex geometry into smaller, manageable elements or mesh. These mesh elements, usually triangles or quadrilaterals in 2D or tetrahedra and hexahedra in 3D, are the building blocks for FEA simulations. The quality of the mesh can significantly impact the accuracy and efficiency of the analysis. This is where meshing services come into play.

The Basics of Meshing

Before we dive into the potential of meshing services, let’s understand the basics of meshing. Meshing involves dividing a complex domain into finite elements, creating a discretized representation of the geometry. There are two main types of meshing:

- Structured Meshing – In this method, elements are arranged in an orderly and regular fashion. This simplifies the calculations but is only suitable for relatively simple geometries.

- Unstructured Meshing – Unstructured meshing is more flexible and adaptable, making it ideal for complex and irregular geometries. It allows for finer meshing in areas of interest while coarser meshing in less critical regions.

The choice between structured and unstructured meshing depends on the complexity of the problem at hand. This decision-making process can benefit significantly from the use of meshing services.

The Role of Meshing Services

Meshing services, often powered by AI and advanced algorithms, offer several key advantages for engineers:

- Automation and Efficiency – One of the primary benefits of meshing services is automation. Advanced algorithms can analyze the geometry and automatically generate a mesh that meets predefined quality and accuracy criteria. This saves engineers a considerable amount of time and reduces the risk of human error.

- Mesh Quality Optimization – Mesh quality is critical in FEA. Poorly generated meshes can lead to inaccurate results and convergence issues. Meshing services can optimize the mesh quality by refining it in areas with high stress or strain, ensuring that the analysis is more accurate and reliable.

- Adaptability – Meshing services can adapt to the specific needs of a project. Whether it’s a simple structure or a highly complex and irregular geometry, these services can adjust the meshing strategy to deliver the best results.

- Parametric Analysis – Some meshing services can perform parametric analysis, allowing engineers to explore multiple design variations efficiently. This is invaluable in the early stages of a project when design decisions can have a significant impact on the final outcome.

- Parallel Processing – In cases where large-scale simulations are required, meshing services often leverage parallel processing, taking advantage of multiple processors or cloud computing. This significantly reduces the time required for analysis and allows for more extensive and detailed simulations.

Applications of Meshing Services

Meshing services are applicable across various industries and engineering disciplines, including:

- Aerospace – Meshing services are crucial for analyzing the structural integrity of aircraft components and ensuring their safety under various loading conditions.

- Automotive – Meshing services are used to optimize the design of automotive components, ensuring their performance and durability under various driving conditions.

- Construction – Meshing services are employed to analyze the structural behavior of buildings and other structures, ensuring their stability and safety under various loading scenarios.

- Biomedical Engineering – Meshing services are used to analyze the behavior of implants, prosthetics, and other biomedical devices, ensuring their biocompatibility and effectiveness.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global Mechanical Industry News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD partner serving the needs of the Mechanical Industry since 2004. MILESTONE focuses on the unique needs of clients and believe in tackling real-life problems with efficiency, smooth and ease.

We support multiple BIM software including SOLIDWORKS, AutoCAD, CATIA etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

You can email us at info@milestonetech.net and can log in to our website www. milestonetech.net to know more about our services and our work portfolio or contact us on +1-844-598-0005