Improving your Engineering Design Process

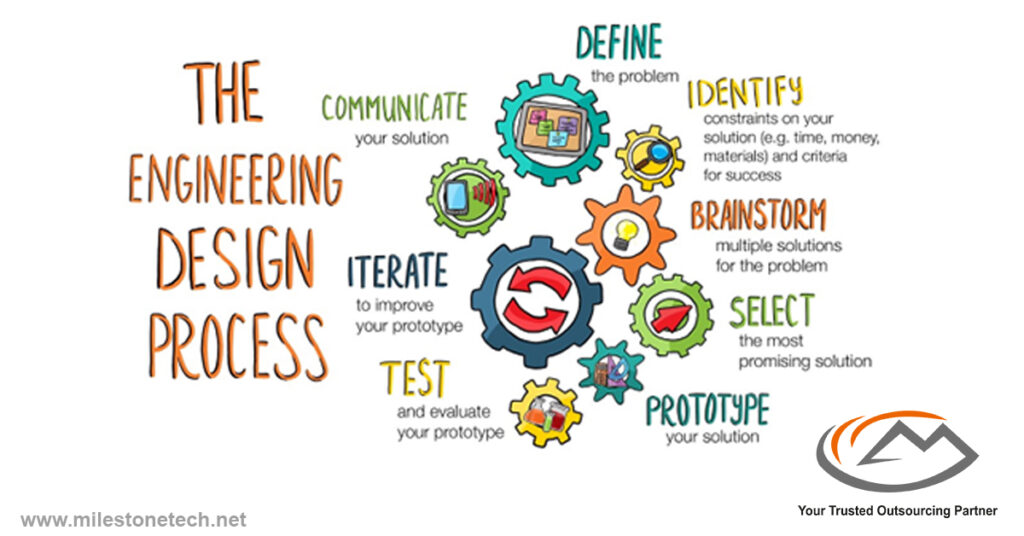

Many engineering projects comprise of technology that the human created and not pre-exist.Innovations, which are designs, may appear from nowhere after the engineer combined technologies to meet people’s needs.Design is the process of making something aesthetically pleasing. Sometimes design is the result of a person who is trying to be quick about it, but design also requires careful planning and a step-by-step approach, so, Improving your Engineering Design Process can be crutial.

A five step process is often used when doing problem solving work in reconstructing problems. Because design problems can be vague and have many relevant answers, the process may need to go back and forth. Solutions are subject to unexpected problems and changes as they grow.Make sure that you identify the problem before you start designing. Typical troubleshooting steps are first identifying what went wrong, then removing possible reasons for the failure (aka why), followed by checking with a trial and error method.

Define the Problem

The work of an engineer is always created with human needs in mind. Designers, sellers, and marketers all have a hand in designing products. The designer will usually identify the problem that needs to be solved, though the need for the solution may go unnoticed to them at first glance. In the private sector, it is always necessary to initiate new construction in order to meet market demand. The company’s success depends on producing a product that people will buy and can make a profit while selling it. Eventually, people establish a need for this product because they will buy and use something if it meets the need for comfort, health, recreation etc. similarly, citizens decide whether to need safe drinking water, roads, fire protection etc.

Gather Apropos Information

In order to design a solution to this problem, you need to gather relevant information. Skipping this step and going straight to the design process can create mistakes and errors in the design process.

Generate Multiple Solution

They are linked. Psychological research has not found a link between intelligence and art. With creativity and intelligence, people build because they can think and act wisely, not be creative because they’re smart or creative in general.

Not all of these characteristics need to be present in order to be creative, but these are some common traits. A great deal of engineering problems is made up by people taking risks and making mistakes together. Thinking about this phase often involves teamwork where many creative solutions are able to be generated and tested.

Analyze & Select a Solution

There are many different types of design solutions, and each one requires a different set of considerations. The different types of analyses you’ll want to do will depend on what particular product you’re designing for. Ergonomics is a field that deals with how humans interact with machines.Many products are designed to work with humans or use the energy or actions of humans. Humans often live in the design and provide design influence, or they may be used as sensors.

Implement the Solution after Testing

The last stage of designing is the implementation which consists of testing, development, and production. The first stage of testing a new design is called prototyping, which consists of building the first fully functional product for a complete construction solution. Products are not thoroughly tested and may not work as intended. They are prototypes which test the design under real conditions.

Traditional construction is sequential, meaning that every step of the process is completed in a sequence. Once you finish one step, you move onto the next. For example: If you create a model from engineering drawings, then you would implement it once the design is complete. The most important part of construction is detailing your work so that others can comprehend what you created.

New advances in 3D CAD tech will address the problem of resource depletion by giving the designers the tools necessary to make last-minute changes or changes. They believe that with rapid prototyping, engineers and manufacturers will be able to create prototypes faster than before.The RP can now simulate engineering processes more efficiently. It compiles parts that are built in different locations into an almost final product. The model differs from the final product, but it is reliable to use for modelling because of such careful design and planning. Rapid prototyping can often be used in a variety of fields, but product designers most commonly use it to create CAD parts. Rapid prototyping “represents specific models” and should also be used as an early step in every production process.

As an engineer, your work includes a combination of judgment, information, modeling and opinions. You will make decisions and hope for better designs. The knowledge-based application can’t effectively take into account all the situations and issues in design when there is a lot of diversity and complexity.

Designers need to be aware of the efficiency of algorithms. Algorithms can speed up design processes by assisting designers in compiling large amounts of data into an easily governed form. Therefore designers must be known to these facts such as:

- The designer needs to confirm the accuracy of the engineering model. An inaccurate model is just as bad and misleading as it would be without an engineering model. Often, adjustments in a model will use the weaknesses of a particular model, if any.

- Algorithms are designed to help designers create a particular design concept. They’re not going to suggest that a different concept would be more appropriate – achieving perfect righteousness depends on choosing the right idea and doing things in abundance.

- Designers often have opposing intentions for their creations. Though many designs encounter challenges, the final product is successful due to the engineers’ diverse considerations.

In the “real” world, one of the consequences of diversity is that a design’s functionality may be compromised. For example, if there are small or large differences in product size, assembly or proper functioning may be an issue. Proper design needs to recognize and prepare for the effects of diversity by avoiding issues such as functional elements being violated.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global CAD, CAM & FEA News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, CAM & FEA services outsourcing partner serving the needs of the Mechanical, Millwork and Automotive industry since 2004. MILESTONE focuses on the unique needs of clients and believe in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with Product Design, 3d Modeling, Drafting & detailing, Reverse Engineering, FEA Analysis and more. We support multiple software including AutoCAD, Solidworks, Catia, NX, Inventor, Solidedge & Ansys etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

For more queries regarding any of the above-mentioned topics, feel free to connect with us on our website www.milestonetech.net or contact us on +1-844-598-0005