Furniture CAD Support| Region: INDIA

Industry: Furniture/ Mill work

CLIENT PROFILE:

- Leading manufacturer/Vendor of Haworth in the United States.

OBJECTIVE:

- To provide full Design support which includes manufacturing Drawings, DXF’s,

ECN (Engineering Change), Fixture design, Technical documentation.

Business Challenge

- Customer required an Design support along with manufacturing drawings.

- The project included components as well as whole product Development cycle including

fixture design work. - Also includes to provide Technical documentation for ease of building assembly using

exploded views. - To complete and submit the parts to customer in short period of time to meet the dead line.

Milestone Solution

- Milestone has provided engineering support services to a growing list of happy clients from around the globe.

- For this project, the team involved Three CAD/Design Engineers and One fixture design expert who have ample experience in providing cad services.

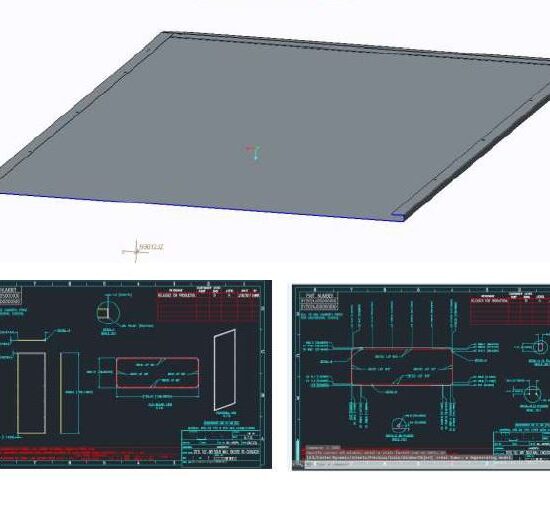

- 3D CAD development and concept as needed, Design review/ Modification and Fixture design.

Production Drawings and DXF:

- The parts mainly are sheet metal parts so the manufacturing process includes operation Laser, Bend, Weld, Assembly and Fixture design

- Once customer send us the 3D model we provide them all the manufacturing drawing’s and DXF which are required at the time of production. Manufacturing Drawings includes laser

Drawing , bend drawing, Weld sequence drawing, Assembly drawing. - We also provide the gauge drawings if the bends are other than 90° which is used to check the angle after production of the parts

Weld fixture:

- Once the manufacturing of parts is done with the help of manufacturing drawings then the fixture design work is initiated.

- Customer want us to design welding fixture for complex assembly using Tab And Slot method.

- For some sub assemblies customer also requires the hand fixtures for small sub assemblies, after which subassemblies are directly placed with the final assembly for weld.

- We create the fixture using the guideline provided by customer that all weld can cover in one single setup wherever possible.

Technical documentation:

- These drawings include the Weld sequence drawings and Assembly drawing step wise.

- Assembly drawings includes the step wise building the complex assembly with the help of exploded view. It is shop floor manual to get better idea to the worker. We can called it as Build Book.

- We also build user manual books which are used to give clear idea how the parts are assembled using exploded views.

BUSINESS IMPACT DELIVERED:

- With proven project management processes and expertise in latest tools, Milestone helps in

reducing time and saves effort on complex designing projects - 60% of cost reduction. As total Engineering work has handled by us.

- Quick Turnaround due to Time difference. This proved very effective as it involves with day to

day routine manufacturing. - Avoid of machining components further reduces cost & manufacturing time.