Chenab Bridge: The Milestone of Modern Railway Engineering

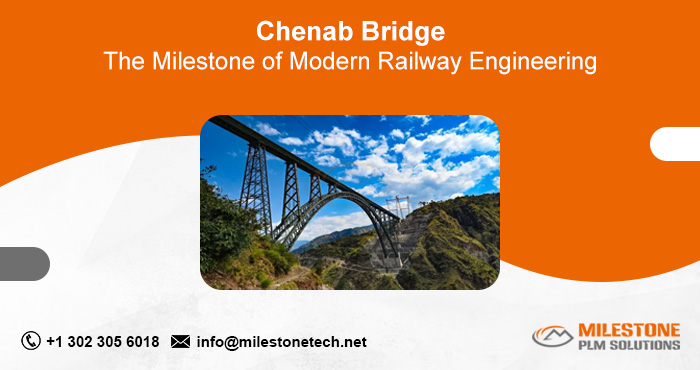

The Chenab Bridge, an extraordinary achievement in the annals of railway engineering, stands tall over the Chenab River in Jammu and Kashmir, India. As part of the ambitious Udhampur-Srinagar-Baramulla Rail Link (USBRL) project, the bridge connects the remote Kashmir Valley to the Indian railway network, transforming both accessibility and strategic mobility.

What makes the Chenab Bridge truly iconic is not just its location but its world record—it’s the highest railway arch bridge on the planet, rising 359 meters above the riverbed, taller than the Eiffel Tower.

Engineering Vision and Planning

Constructing a bridge of such magnitude in one of the world’s most challenging terrains demanded meticulous planning, pioneering techniques, and unwavering determination. The idea was conceived in early 2000s as part of the USBRL to link Jammu to Baramulla. This meant overcoming massive geographical and geological challenges.

The Chenab Bridge is designed to withstand seismic activity, strong winds up to 266 km/h, and temperature fluctuations from -20°C to 45°C. The alignment had to be extremely precise, as any error in this mountainous region could compromise safety.

Key Stakeholders:

- Indian Railways

- Konkan Railway Corporation

- Afcons Infrastructure and DRS (Deutsche Bahn) for design and consultancy

Structural Design and Technical Features

The Chenab Bridge is an arch-shaped steel and concrete structure that spans 1,315 meters, with the main arch measuring 467 meters. The use of steel for the superstructure ensures flexibility and strength, ideal for the seismic-prone zone.

Key Structural Highlights:

- Height: 359 meters (above riverbed)

- Length: 1,315 meters

- Arch Span: 467 meters

- Deck Width: 13.5 meters

- Materials Used: Over 24,000 metric tonnes of steel

The bridge comprises two key components:

-

The Arch: A two-ribbed arch composed of steel trusses, designed to resist buckling forces.

-

Deck: Constructed using orthotropic steel plates, allowing for high bending resistance.

The arch design was chosen for its ability to span deep gorges without the need for multiple piers, which are unfeasible in a deep valley.

Construction Techniques and Innovations

The construction of the Chenab Bridge showcased cutting-edge engineering, especially due to the challenges posed by geography, weather, and safety.

1. Cable Crane System: Since conventional cranes couldn’t span the gorge, engineers installed one of the world’s longest cable crane systems between mountain slopes. It enabled the precise placement of steel segments.

2. Incremental Launching Technique: Portions of the bridge were assembled on the banks and then launched across the gorge incrementally. This technique minimized the need for risky work over the valley.

3. Rock Anchoring: The foundation was anchored deep into the rock strata using rock bolts and micro-piles to ensure stability during earthquakes or landslides.

4. Robotic and Drone Surveillance: To ensure safety and precision, robotic scanners and drone-based surveys were used throughout construction for inspection and alignment checks.

Challenges and Risk Mitigation

The bridge construction faced several hurdles:

- Seismic Activity: The region lies in Seismic Zone IV, demanding a structure that could handle major earthquakes.

- Wind Speeds: Wind tunnel testing was conducted in Denmark to simulate up to 266 km/h wind speeds.

- Weather Extremes: From snow to blistering sun, the bridge had to be resistant to a wide range of conditions.

Safety Innovations:

- Blast-proof design to mitigate any potential terror threats.

- Structural health monitoring system for real-time tracking of stress and vibration.

- Wind Shield Barriers to protect trains from gusty winds.

Time and Cost Metrics

The project was initially expected to be completed by 2009, but due to terrain challenges, redesigns, and political factors, the timeline extended by more than a decade.

Timeline:

-

Project Start: 2004

-

Main Arch Completion: April 2021

-

Bridge Completion: Expected by 2024

-

Train Operations: Expected to begin post safety clearance in 2025

Estimated Cost:

-

₹1,486 crore (approx. $200 million)

Though delayed, the extended timeline ensured that every safety and engineering measure was met with the highest standard.

Global Recognition and Legacy

The Chenab Bridge is not only a symbol of Indian engineering prowess but also a project that puts India on the global infrastructure map. It has:

- Set new benchmarks in bridge design and construction in hostile terrains.

- Inspired future high-altitude railway projects globally.

- Demonstrated how advanced construction technologies can transform inaccessible regions.

It is likely to be recognized by global civil engineering bodies like the American Society of Civil Engineers and has already received acclaim for its sustainability and innovation.

Conclusion: A Bridge Beyond Steel

The Chenab Bridge is more than just a link between two points—it’s a bridge between vision and reality. It showcases what human ingenuity, combined with modern engineering and technology, can achieve even in the most challenging conditions.

From its record-breaking height to the sophisticated technology used, the Chenab Bridge will not just serve as a transportation route but also as a monumental milestone in modern railway engineering.

For India, it is a testament to resilience, progress, and the future of infrastructure development.

Follow Milestone PLM Solutions for AEC Industry Updates, CAD Tips and Global Construction News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, BIM outsourcing partner serving the needs of the AEC industry since 2004. MILESTONE focuses on the unique needs of clients and believe in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with DD Set, CD Set, BIM Modeling, Rendering, walk through and more. We support multiple BIM software including AUTOCAD REVIT, Architecture cad, Cabinet Vison, Vector works etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers & Architects, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

You can email us at info@milestonetech.net and can log in to our website www. milestonetech.net to know more about our services and our work portfolio or contact us on +1-302-305-6018