SlotsMillion Casinon arvostelu ( Päivitys 2024 )

SlotsMillion Casino pyrkii olemaan lopullinen määränpääsi kolikkopeleille.

Vuonna 2020, jos etsit ensiluokkaista kolikkopelikasinoa, SlotsMillionin pitäisi olla listasi kärjessä. Se tarjoaa vaikuttavan kokoelman yli 3 000 peliä yli 100 kehittäjältä, ja se tarjoaa laajan valikoiman pelejä, joita harva muu kasino pystyy tarjoamaan. Nopeiden kotiutusten ja säännöllisten kampanjoiden ohella SlotsMillion erottuu edukseen, vaikka sen VR-kasinoprojekti onkin tällä hetkellä jäissä. Tutustutaanpa siihen, mitä tällä ylistetyllä kolikkopelioperaattorilla on tänään tarjottavanaan.

Tervetuliaisbonukset SlotsMillion Casinolla

Uusille pelaajille Irlannissa SlotsMillion tarjoaa anteliaan tervetuliaisbonuksen. Tehdessään ensitalletuksen, joka vaihtelee 20 ja 100 euron välillä, pelaajat saavat 100 % bonuksen.

Mutta odota, on vielä muutakin! Viiden päivän aikana pelaajat saavat myös 20 ilmaiskierrokset slotsmillionissa joka päivä.

Erityisbonukset

Naisten ilta: Saat 40 %:n ottelubonuksen 100 euroon asti, joka on yksinomaan naispelaajien saatavilla. Saadaksesi oikeutuksen tee 25 euron talletus maanantaina kello 19-23 välisenä aikana ja nauti bonuksesta tavanomaisen kierrätysvaatimuksen mukaisesti.

- Herrasmiesten ilta: Nauti 40 %:n bonuksesta 100 euroon asti, joka on saatavilla miespelaajille keskiviikkoisin. Ehdot ovat samat kuin Ladies’ Nightissa.

- Slunchbreak: Talleta vähintään 20 € maanantaista perjantaihin klo 11 ja 13 välillä paikallisen aikavyöhykkeesi mukaan ja saat 20 ilmaiskierrosta.

- Perjantain Happy Hour: Talleta perjantaina kello 19.00-23.00 välisenä aikana ja saat 50 %:n talletusbonuksen 100 euroon asti ensitalletuksestasi. Saadaksesi täyden 100 €:n bonuksen tee neljä 50 €:n talletusta kukin.

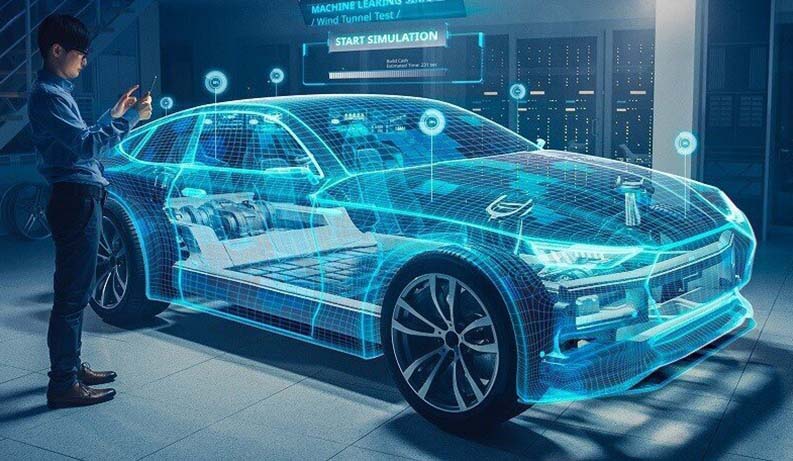

Industries We Serve

Milestone | Your Trusted Outsourcing Partner

We understand the commercial realities of bringing new products to market and the pressure you’re under to design within budget and ahead of forecast.

At Milestone, we are committed to provide quality Engineering Design & BIM Services at competitive rates so that you can always stay ahead of your competition.

- 19+ Years In Industry

- ISO 9001:2015 & ISO 27001:2013 Certified Company

- Ranked among Top Engineering consulting companies

- More than 25% of employees with 5+ years of association

- Senior management with average span of 12+ years of experience